- Hydraulic changer:

- since 1985 -

- since 1985 -

Output:110-160kg/h

Max speed:25M/min

Screw L/D ratio is 34:1

Film width(mm):From 1600 to 2500

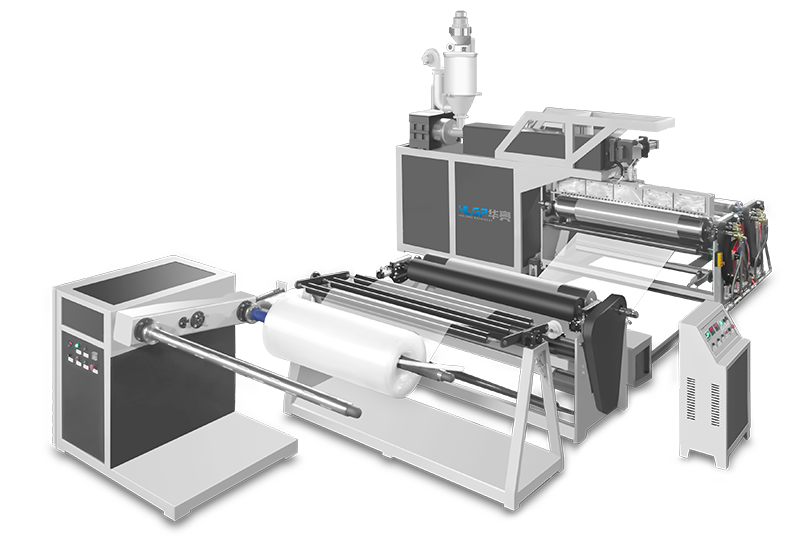

2 layer bubble film extruder primarily consists of an extruding unit, a forming unit, a winding unit and an electrical control unit. Raw materials such as LDPE, LLPDE,HDPE,PP and recycled materials are extruded by single screw extruder at high temperature to produce bubble films.

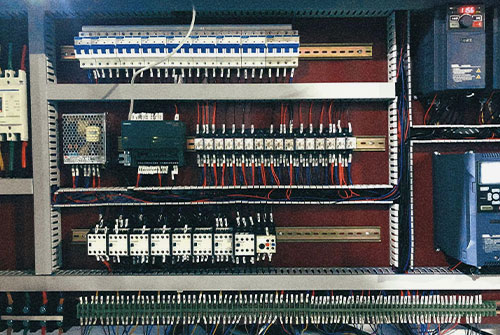

Bubble are formed by bubble roller and water cooling for faster and higher-quality film production.The PLC can control and monitors the machine and temperature.The bubble film making machine is equipped with automatic winding.meter counting alarming,which make it highly efficient.

2 layer bubble film is an excellent packing material because of its low cost nature and because its floppy bubble acts as a shockproof buffer to make sure that customers can get intact products and to prevent unnecessary loss. It is widely used in countless products including machine part, electric part, cosmetics, radiator and artifacts.

|

Model |

HLPE-1600 |

HLPE-2000 |

HLPE-2500 |

|

Screw dia (mm) |

80 |

90 |

100 |

|

L/D |

34:1 |

34:1 |

34:1 |

|

Motor |

30kw |

45kw |

55kw |

|

Final product (mm) |

1600 |

2000 |

2500 |

|

Output |

110KG |

150KG |

160KG |

|

Total power/Heating power |

85/47kw |

110/60kw |

140/75kw |

|

Line speed |

25m/min |

25m/min |

25m/min |

|

Volt/Ph/Line/Hz |

380/3/4/50 |

380/3/4/50 |

380/3/4/50 |

|

L*W*H (mm) |

9300x2900x2500 |

9600x3300x2500 |

10000x3800x2500 |

|

Material |

LDPE/LLDPE |

LDPE/LLDPE |

LDPE/LLDPE |

|

Output |

Customized by configuration |

||

Electricity Consumption (kWh) 24 hours

2016.00 (degree)Finished Width (m)

1.60 (m)Finished thickness (thickness per square meter)

50.00Speed (per minute)

2.50Extrusion volume (24 hours)

0.00Raw material cost (per ton)

Labor origin (24 hours)

Labor origin (24 hours)

Total cost

0