- Hydraulic changer:

- since 1985 -

- since 1985 -

2-layer bubble film is a protective packaging material consisting of two layers of polyethylene film with air-filled bubbles in between. It provides excellent cushioning and shock absorption, while being lightweight, flexible, and insulating. It is widely used across various industries to package fragile items during shipping and handling.

Out put: 110-160kg/h

Max speed: 25M/min

Screw L/D ratio is 34:1

Film width(mm):From 1600 to 2500

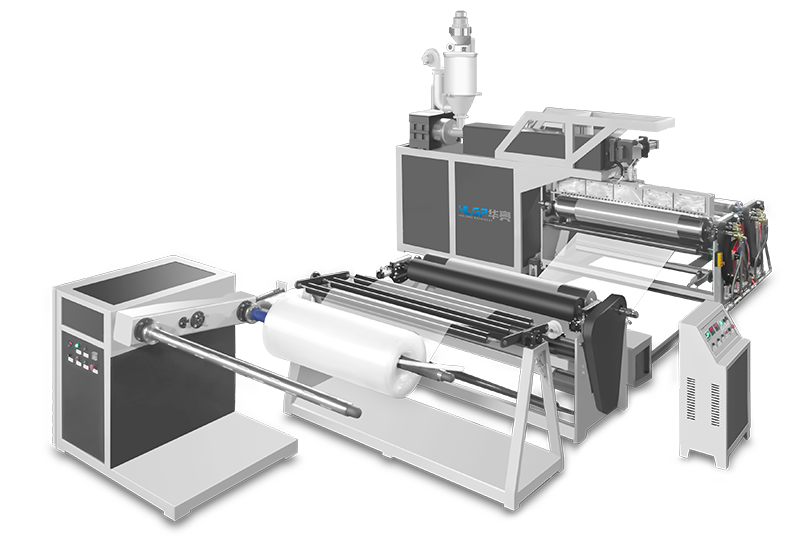

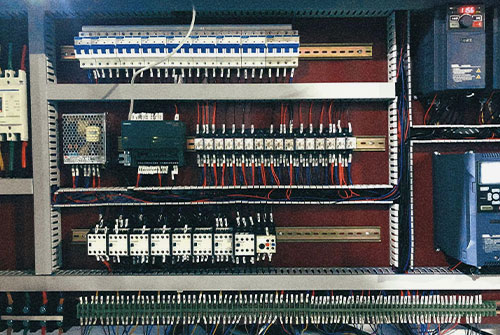

The 2-layer bubble film extruder consists of the following main components: Extruding Unit, Forming Unit, Winding Unit, Electrical Control Unit

Raw materials such as LDPE, LLDPE, HDPE, PP, and recycled materials are fed into a single-screw extruder, where they are melted at high temperatures to produce the bubble film.

Film Production Process

Bubbles are formed by a bubble roller and water cooling system, which ensures faster production and higher quality film. The system is controlled by a PLC (Programmable Logic Controller) that monitors both the machine and temperature, ensuring optimal performance.

The bubble film machine is also equipped with automatic winding and meter counting alarming, which contribute to its high efficiency.

Automatic Cutting Function

The 2-layer bubble film machine features an automatic cutting function that helps reduce labor costs and improve production efficiency. This feature is particularly beneficial for high-volume production scenarios, streamlining the manufacturing process.

Applications of 2-Layer Bubble Film

2-layer bubble film is an excellent packaging material, prized for its cost-effectiveness and ability to act as a shockproof buffer, ensuring that products arrive intact and preventing unnecessary losses. It is commonly used in the packaging of a wide range of products, including: Machine parts, Electronic components, Cosmetics, Radiators, Artifacts

|

Model |

HLPE-1600 |

HLPE-2000 |

HLPE-2500 |

|

Screw dia (mm) |

80 |

90 |

100 |

|

L/D |

34:1 |

34:1 |

34:1 |

|

Motor |

30kw |

45kw |

55kw |

|

Final product (mm) |

1600 |

2000 |

2500 |

|

Output |

110KG |

150KG |

160KG |

|

Total power/Heating power |

85/47kw |

110/60kw |

140/75kw |

|

Line speed |

25m/min |

25m/min | 25m/min |

|

Volt/Ph/Line/Hz |

380/3/4/50 |

380/3/4/50 |

380/3/4/50 |

|

L*W*H (mm) |

9300x2900x2500 |

9600x3300x2500 |

10000x3800x2500 |

|

Material |

LDPE/LLDPE |

LDPE/LLDPE |

LDPE/LLDPE |

|

Output |

Customized by configuration |

||

Electricity Consumption (kWh) 24 hours

2016.00 (degree)Finished Width (m)

1.60 (m)Finished thickness (thickness per square meter)

50.00Speed (per minute)

2.50Extrusion volume (24 hours)

0.00Raw material cost (per ton)

Labor origin (24 hours)

Labor origin (24 hours)

Total cost

0