- Hydraulic changer:

- since 1985 -

- since 1985 -

Out put:170-250kg/h

Max speed:35M/min

Screw L/D ratio is 34:1

Film width :From 1600 to 2500

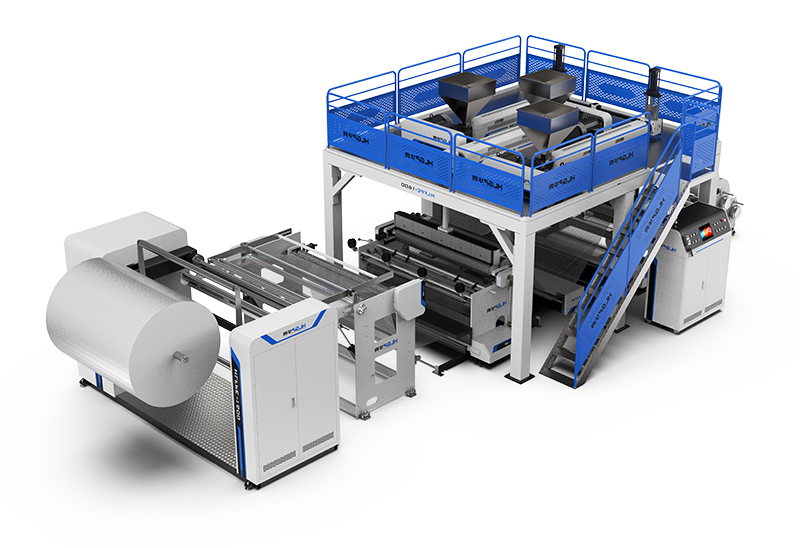

3-Layer Bubble Film Extruder Overview

The 3-layer bubble film extruder primarily consists of an extruding system, a forming system, a winding system, and an electric control system. Raw materials such as LDPE, LLPDE, HDPE, PP, and recycled materials are first extruded by the main extruding system at very high temperatures to produce bubble films. These films are then passed through a secondary extruding system to add an additional PE film layer, enhancing the strength and versatility of the final product.

Bubble Formation and Cooling Process

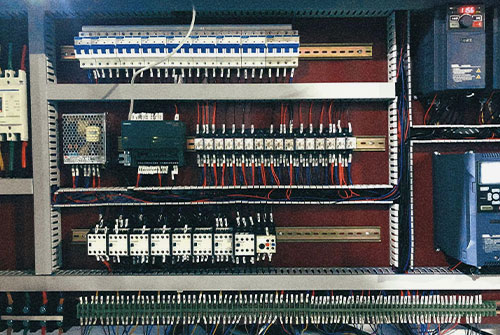

Bubbles are formed through the bubble roller and water cooling system, ensuring faster production speeds and higher-quality films. The cooling system plays a crucial role in solidifying the bubbles and maintaining consistent film thickness. The PLC (Programmable Logic Controller) is responsible for controlling and monitoring both the machine and the temperature, ensuring optimal performance and precision during the production process.

High Efficiency and Automation Features

The bubble film making machine is equipped with a range of automation features, including:

1.Automatic Cutting: Ensures precise cutting and reduces labor costs.

2.Automatic Winding: Increases efficiency by automatically winding the film without manual intervention.

3.Meter Counting Alarming: Tracks the amount of film produced, enhancing production management.

4.Cutting Function: Allows for quick and accurate cutting of the bubble film, improving overall productivity.

Customizable Options and Advanced Components

1.In-Line Film Edge Trim Winder: Efficiently removes excess material from the edges of the film during production.

2.Bubble Film Perforator: Adds perforations to the film, providing greater flexibility for different applications.

3.Hydraulic Screen Changer: Allows for easy replacement of filters and ensures smooth and continuous production.

Properties and Applications of 3-Layer Bubble Film

3-layer bubble film is an impact-resistant, moisture-proof, and shockproof material that is highly suitable for packaging. It is non-toxic, tasteless, and offers excellent shock absorption, impact resistance, heat resistance, moisture resistance, corrosion resistance, and transparency. These qualities make it an ideal material for protecting sensitive products during shipping and storage.

This versatile bubble film is widely used in packaging for:

1.Electronics and Machine Parts: Providing reliable protection during transport.

2.Consumer Goods: Ensuring safe delivery of products like cosmetics and household items.

3.Industrial Applications: Offering superior protection for machinery and components.

With its outstanding physical properties and efficiency in production, 3-layer bubble film is a preferred choice for a wide range of packaging applications.

|

Model |

HLFPE-1600 |

HLFPE-2000 |

HLFPE-2500 |

HLFPE-3000 |

|

Product Width |

1600mm |

2000mm |

2500mm |

3000mm |

|

Screw dia (mm) |

80/60 |

90/70 | 90/70 | 100/80 |

|

L/D |

34:1 |

34:1 |

34:1 |

34:1 |

|

Output |

170Kg |

200Kg |

200Kg |

250Kg |

|

Motor |

30/15KW |

45/22KW |

45/22KW |

55/30KW |

|

Total power/Heating power |

155/95KW |

200/120KW |

200/120KW |

255/165KW |

|

L*W*H (mm) |

12000x4800x3200 |

12000x5100x3200 |

12000x5300x3200 |

12000x5500x3200 |

|

Line speed |

35m/min |

|||

|

Volt/Ph/Line/Hz |

380/3/4/50 |

|||

|

Material |

LDPE/LLDPE |

|||

|

Output |

Customized by configuration |

|||

Electricity Consumption (kWh) 24 hours

0.00 (degree)Finished Width (m)

0.00 (m)Finished thickness (thickness per square meter)

0.00Speed (per minute)

0.00Extrusion volume (24 hours)

0.00Raw material cost (per ton)

Labor origin (24 hours)

Labor origin (24 hours)

Total cost

0