- Hydraulic changer:

- since 1985 -

- since 1985 -

Out put:220-450kg/h

Max speed:35M/min

Screw L/D ratio is 34:1

Film width :From 1600 to 2500

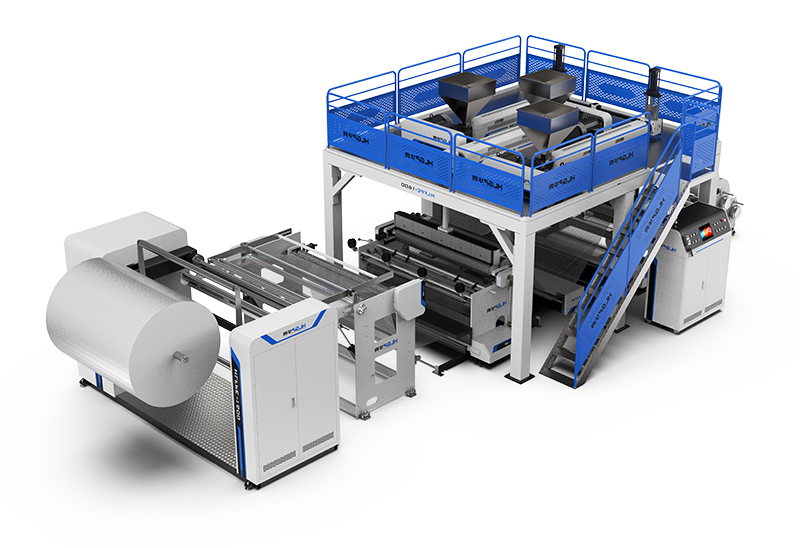

5-Layer Bubble Film Extruder Overview

The 5-layer bubble film extruder primarily consists of an extruding system, a forming system, a winding system, and an electric control system. Raw materials such as LDPE, LLPDE, HDPE, PP, and recycled materials are first extruded at a very high temperature by the main extruding system to produce bubble films. These bubble films are then processed further by the secondary extruding system, which adds an additional PE film. The unwinder can laminate materials like pearl wool, Kraft paper, and aluminum film to the outer layer of the bubble film.

Advantages of 5 Extruders

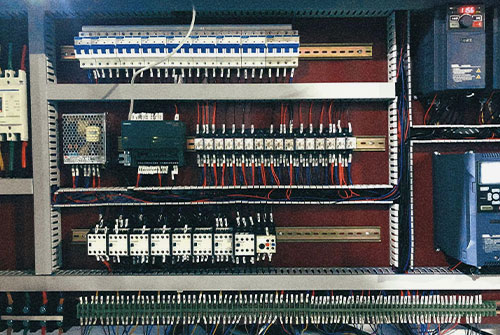

Compared to a 3-screw extruder, the 5-layer extruder allows the separate control of the thickness of the bubble layer and the base layer, which helps in saving material costs. This flexibility enables the production of bubble films in various colors, offering diverse options for customization. Additionally, this machine is designed for steady operation, ensuring consistent quality in production. The PLC system controls and monitors both the machine and the temperature, optimizing the extrusion process.

High-Efficiency Features

The bubble wrap making machine is equipped with automatic cutting, automatic winding, meter counting, alarming, and cutting functions, making it highly efficient. These features enhance the overall productivity of the machine. Moreover, the machine comes with several selectable parts, such as the in-line film edge trim winder, bubble film perforator, and hydraulic screen changer, allowing for greater flexibility and customization during production.

5-Layer Bubble Film Applications

5-layer bubble film is an innovative, eco-friendly thermal insulation material that is soft, lightweight, and easy to install. It effectively blocks sunlight while offering improved thermal insulation, waterproofing, and moisture-proof capabilities. Produced by combining polyethylene bubble films with aluminum foils, it surpasses traditional materials like glass fabrics and foamed materials in terms of comfort and environmental friendliness. Additionally, it provides effective blocking of infrared radiation, a feature not found in common insulation materials such as iron sheets, concrete, and wood.

|

Model |

HLFPE-1600 |

HLFPE-2000 |

HLFPE-2500 |

HLFPE-3000 |

|

Product Width |

1600mm |

2000mm |

2500mm |

3000mm |

|

Screw dia |

70.60/60/70.60 |

80.70/70/80.70 |

80.70/70/80.70 |

90.80/80/90.80 |

|

L/D |

34:1 |

34:1 |

34:1 |

34:1 |

|

Output |

220Kg |

270Kg |

320Kg |

450Kg |

|

Motor |

22/15/15/22/15kw |

30/22/22/30/22kw |

30/22/22/30/22kw |

45/37/37/45/37kw |

|

Total power/Heating power |

205/105kw |

263/127kw |

271/135kw |

381/180kw |

|

L*W*H |

16000x4800x3200 |

16000x5100x3200 |

16000x5300x3200 |

16000x5500x3200 |

|

Volt/Ph/Line/Hz |

380/3/4/50 |

|||

|

Line speed |

35m/min |

|||

|

Material |

LDPE/LLDPE |

|||

|

Output |

Customized by configuration |

|||

Electricity Consumption (kWh) 24 hours

0.00 (degree)Finished Width (m)

0.00 (m)Finished thickness (thickness per square meter)

0.00Speed (per minute)

0.00Extrusion volume (24 hours)

0.00Raw material cost (per ton)

Labor origin (24 hours)

Labor origin (24 hours)

Total cost

0