- Hydraulic changer:

- since 1985 -

- since 1985 -

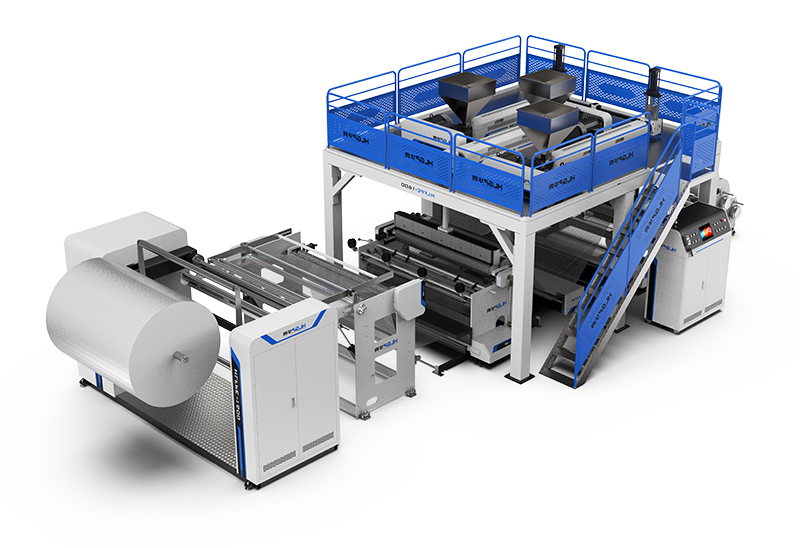

Out put:220-450kg/h

Max speed:35M/min

Screw L/D ratio is 34:1

Film width :From 1600 to 2500

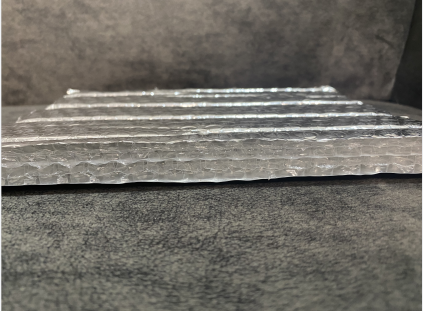

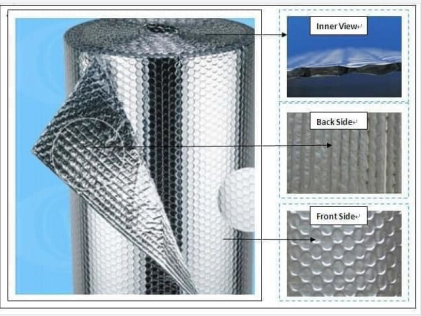

The 7-layer bubble film extruder is primarily composed of an extruding system, a forming system, an aluminum composite film lamination rack, a winder, and an electronic control system. The machine uses two sets of main extruders with twin screws and one set of a secondary extruder with a single screw to produce 5-layer bubble films. In addition, composite materials such as aluminum foil, Kraft paper, and EPE foam can be incorporated during the process. The machine offers various optional parts, including an in-line edge trim winder, an in-line perforation unit, and a hydraulic screen changer.

5 Extruders:

Compared to 3-screw extruder machines, the 5-screw extruder machines enable independent control of both the bubble layer and base layer thickness, leading to an improved composite effect.

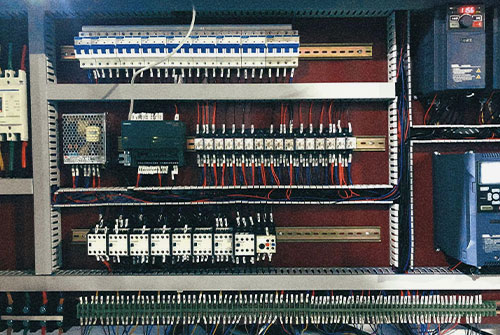

The PLC system is designed to control and monitor the machine, including temperature management. The bubble film making machine is equipped with automatic cutting, automatic winding, meter counting with alarming functions, and cutting capabilities, all of which contribute to enhanced operational efficiency.

Applications of 7-Layer Double Aluminum Foil Laminated Bubble Film:

The 7-layer double aluminum foil laminated bubble film, due to its excellent thermal insulation properties, is widely used across various industries, including construction, luggage, refrigeration, and packaging. It serves as an impact-resistant and expansion-proof material in construction, used in roads, airfield runways, culverts, and bridges. It can also be installed on roofs, walls, and floors to block up to 80% of heat exchange between buildings and the environment, effectively protecting walls and maintaining interior temperatures. Additionally, an extra protective layer improves its thermal insulation effect by preventing heat loss, ensuring better temperature control.

|

Model |

HLFPE-1600 |

HLFPE-2000 |

HLFPE-2500 |

HLFPE-3000 |

|

Product Width |

1600mm |

2000mm |

2500mm |

3000mm |

|

Screw dia |

70.60/60/70.60 |

80.70/70/80.70 |

80.70/70/80.70 |

90.80/80/90.80 |

|

L/D |

34:1 |

34:1 |

34:1 |

34:1 |

|

Output |

220Kg |

270Kg |

320Kg |

450Kg |

|

Motor |

22/15/15/22/15kw |

30/22/22/30/22kw |

30/22/22/30/22kw |

45/37/37/45/37kw |

|

Total power/Heating power |

205/105kw |

263/127kw |

271/135kw |

381/180kw |

|

L*W*H |

16000x4800x3200 |

16000x5100x3200 |

16000x5300x3200 |

16000x5500x3200 |

|

Volt/Ph/Line/Hz |

380/3/4/50 |

|||

|

Line speed |

35m/min |

|||

|

Material |

LDPE/LLDPE |

|||

|

Output |

Customized by configuration |

|||

Electricity Consumption (kWh) 24 hours

0.00 (degree)Finished Width (m)

0.00 (m)Finished thickness (thickness per square meter)

0.00Speed (per minute)

0.00Extrusion volume (24 hours)

0.00Raw material cost (per ton)

Labor origin (24 hours)

Labor origin (24 hours)

Total cost

0