- Hydraulic changer:

- since 1985 -

- since 1985 -

Out put:165-180kg/h

Max speed:35M/min

Screw L/D ratio is 34:1

Film width :From 1600 to 2500

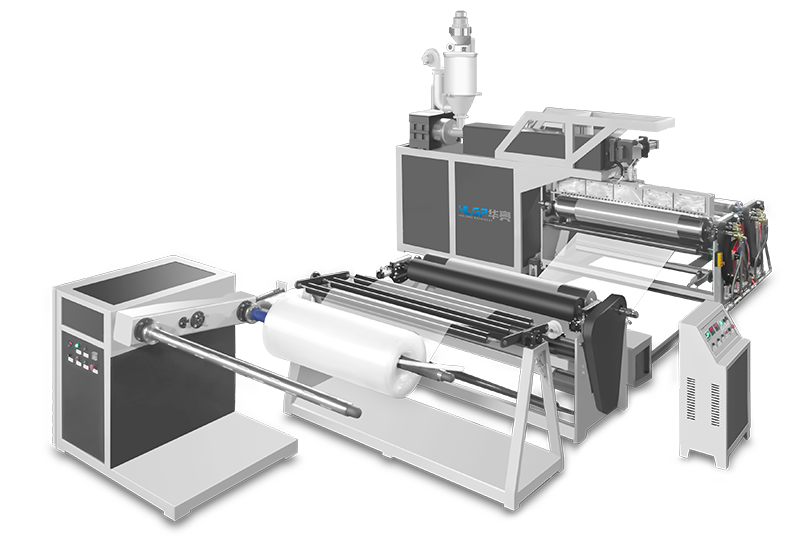

2-Layer Bubble Film Extruder Overview

The 2-layer bubble film extruder consists of an extruding unit, a forming unit, a winding unit, and an electrical control unit. Raw materials such as LDPE, LLDPE, HDPE, PP, and recycled materials are extruded by a single screw extruder at high temperatures to produce bubble films.

Bubble Formation and Production Process

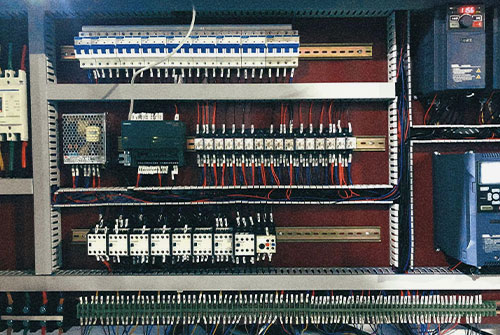

The bubble formation is achieved through a bubble roller, followed by water cooling, ensuring faster and higher-quality film production. The PLC system controls and monitors both the machine and the temperature, ensuring consistent and efficient operation. The bubble film making machine is also equipped with automatic winding and meter counting alarming functions, which enhance its overall efficiency.

Twin Screw Extruder Advantage

Compared to a single screw extruder, the air bubble film twin screw extruder offers several advantages. It can independently control the thickness of both the bubble layer and the base layer, which helps reduce material costs. Additionally, the twin screw extruder allows for the use of different raw material formulas to produce bubble films in various colors, providing the machine with more stable operation and greater flexibility in production.

Benefits of 2-Layer Bubble Film

2-layer bubble film is an excellent packaging material due to its low cost and shock-absorbing properties. The flexible bubbles act as a buffer, protecting products from damage during transit and preventing unnecessary loss. This makes 2-layer bubble film a popular choice for a wide range of products, including machine parts, electrical components, cosmetics, radiators, and delicate artifacts.

The 2-layer bubble film extruder offers a cost-effective and efficient solution for producing high-quality bubble films. Its versatile design, including the option of using twin screw extruders for more precise control, makes it suitable for various applications. Whether for packaging or protective purposes, 2-layer bubble film is an ideal material for ensuring product safety and reducing costs.

|

Model |

HLPE-1600 |

HLPE-2000 |

HLPE-2500 |

|

Screw dia (mm) |

70/60 |

80/70 | 90/70 |

|

L/D |

34:1 |

34:1 |

34:1 |

|

Motor |

22/15KW |

30/22KW |

45/22KW |

|

Final product |

1600 |

2000 |

2500 |

|

Output |

165KG/H |

180KG/H | 180KG/H |

|

Total power/Heating power |

85/47kw |

110/60kw |

140/75kw |

|

Line speed |

35m |

35m |

35m |

|

Volt/Ph/Line/Hz |

380/3/4/50 |

380/3/4/50 |

380/3/4/50 |

|

L*W*H (mm) |

9300x2900x2500 |

9600x3300x2500 |

10000x3800x2500 |

|

Material |

LDPE/LLDPE |

LDPE/LLDPE |

LDPE/LLDPE |

|

Output |

Customized by configuration |

||

Electricity Consumption (kWh) 24 hours

2016.00 (degree)Finished Width (m)

1.60 (m)Finished thickness (thickness per square meter)

50.00Speed (per minute)

2.50Extrusion volume (24 hours)

0.00Raw material cost (per ton)

Labor origin (24 hours)

Labor origin (24 hours)

Total cost

0