- Hydraulic changer:

- since 1985 -

- since 1985 -

Out put:200-450kg/h

Max speed:40M/min

Screw L/D ratio is 34:1

Film width :From 1600 to 3000

3-Layer Bubble Film Extruder Overview

The 3-layer bubble film extruder primarily consists of an extruding system, a forming system, a winding system, and an electric control system. Raw materials such as LDPE, LLDPE, HDPE, PP, and recycled materials are first fed into the main extruding system, where they are heated to very high temperatures to produce the initial bubble films. Subsequently, an additional PE film is applied to these bubble films using the secondary extruding system. The bubbles are then formed through a bubble roller and water cooling process, which ensures faster production and higher-quality film output. The PLC (Programmable Logic Controller) system controls and monitors both the machine operations and temperature to maintain consistent performance.

Key Features

1.Automatic Functions: The machine is equipped with automatic cutting, automatic winding, meter counting alarming, and cutting functions, all of which contribute to its high efficiency and smooth operation.

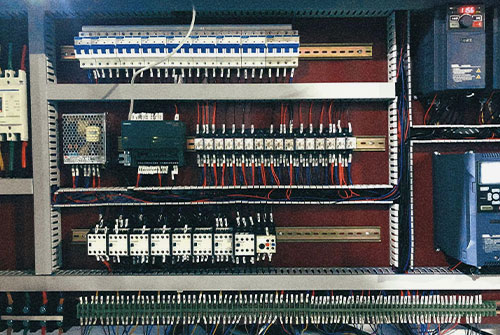

2.Customizable Parts: The extruder includes many selectable parts such as an in-line film edge trim winder, bubble film perforator, and hydraulic screen changer, allowing for greater flexibility in production.

Advantages of 3 Extruders

Compared to a 2-screw extruder system, the 3-layer extruder provides enhanced control over the thickness of both the bubble layer and the base layer. This independent control leads to material cost savings. The system also allows for the use of different formulas, enabling the production of bubble films in various colors. Additionally, the 3-layer system ensures more stable operation, making it ideal for large-scale, high-demand production.

Benefits of 3-Layer Bubble Film

1.Impact-Resistance & Shockproof: The bubble structure provides excellent shock absorption, protecting delicate items during transport.

2.Moisture-Proof: It effectively shields contents from moisture, making it ideal for products sensitive to environmental conditions.

3.Chemical Resistance: The film is resistant to various chemicals, enhancing its protective properties.

4.Additional Benefits: It is non-toxic, tasteless, and provides heat resistance, corrosion resistance, and transparency.

These properties make 3-layer bubble film an excellent choice for packaging a wide variety of products, including fragile electronics, industrial components, and consumer goods.

The 3-layer bubble film extruder is an advanced and efficient machine designed to produce high-quality bubble films for protective packaging. With its ability to control the thickness of each layer independently, use different material formulas, and incorporate customizable parts, it offers a versatile solution for a range of applications. Whether for impact resistance, moisture protection, or shock absorption, 3-layer bubble film ensures the safe delivery of products while reducing material costs.

|

Model |

HLFPE-1600 |

HLFPE-2000 |

HLFPE-2500 |

HLFPE-3000 |

|

Product Width |

1600mm |

2000mm |

2500mm |

3000mm |

|

Screw dia (mm) |

70/60/60 |

80/70/70 |

90/70/70 |

100/90/90 |

|

L/D |

34:1 |

34:1 |

34:1 |

34:1 |

|

Output |

200Kg |

250Kg |

300Kg |

450Kg |

|

Motor |

22/15/15KW |

30/22/22KW |

30/22/22KW |

45/37/37KW |

|

Total power/Heating power |

155/95KW |

200/120KW |

200/120KW |

255/165KW |

|

L*W*H (mm) |

12000x4800x3200 |

12000x5100x3200 |

12000x5300x3200 |

12000x5500x3200 |

|

Line speed |

40m/min |

|||

|

Volt/Ph/Line/Hz |

380/3/4/50 |

|||

|

Material |

LDPE/LLDPE |

|||

|

Output |

Customized by configuration |

|||