- since 1985 -

- since 1985 -

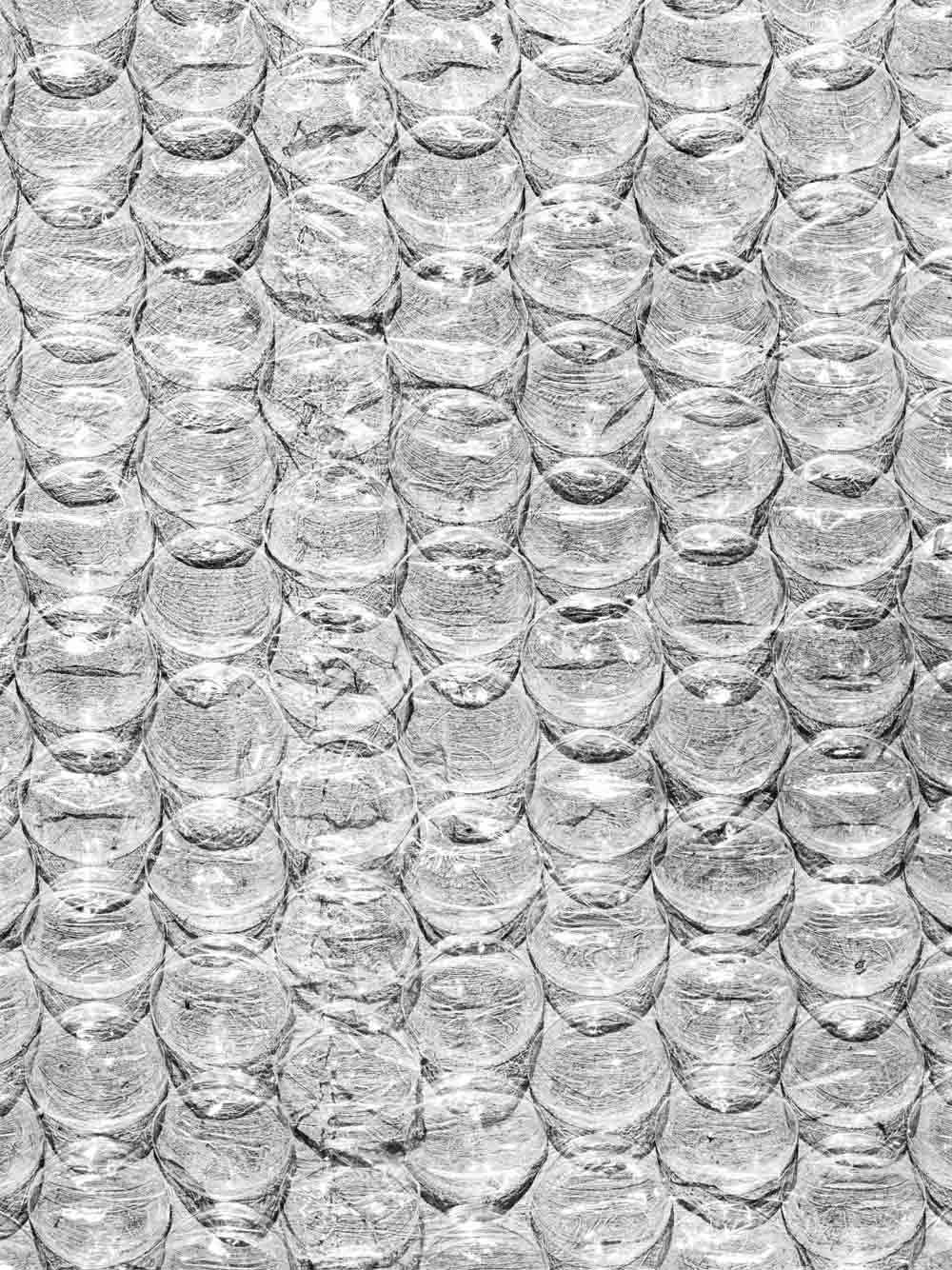

Many people have noticed that when purchasing various items, especially delicate and fragile ones, there is often a layer of bubble wrap inside the packaging box.

Some even enjoy the simple pleasure of popping the bubbles on the wrap to relieve stress.

Bubble wrap is a packaging material made by enclosing air within thin films.

Bubble wrap serves to protect products from impacts, dampen vibrations during transportation, and provides thermal insulation. It is suitable for packaging and handling various products across different industries.

Bubble wrap is commonly produced using the extrusion lamination method.

A machine simultaneously extrudes two layers of film.

One of these layers is formed into bubbles on a vacuum roller, then thermally laminated with the other layer.

The laminated film is pulled and wound into rolls, resulting in double-layered composite bubble wrap.

When people purchase large appliances or move furniture, they often encounter this material, which prevents items from being damaged during transportation.

An indispensable piece of machinery in the production of bubble wrap is the bubble film machine.

Bubble wrap essentially consists of a film with air bubbles trapped in between its layers.

From a physics perspective, it's important to note that the air inside the bubbles doesn't need to be completely full for the wrap to be effective. Overinflated bubbles lack the necessary elasticity and are more likely to burst with slight pressure.

Typically, ideal bubble wrap should have the air inside the bubbles occupying about 4/3 of the total volume of each bubble.

Manufacturers of bubble wrap primarily use materials such as high-density polyethylene and linear low-density polyethylene.

If colored bubble wrap is required, an appropriate amount of coloring agent is added to the resin during the production process.

Anti-static bubble wrap is made by adding anti-static agents to a mixture of polyethylene and linear low-density polyethylene, and it's produced through a bubble extrusion process.

Equipment selection for the extrusion process typically involves using a general-purpose extruder for PE material.

When it comes to the bubble wrap's characteristics, its weight per square meter can be adjusted when the mold is fixed.

This weight, usually measured in kilograms per square meter, indicates the wrap's thickness. Heavier eco-friendly bubble wrap implies a higher usage of raw materials, consequently resulting in a higher price per square meter.

1. Single-bubble

Single-bubble wrap is suitable for protecting lightweight products

2. Double-bubble

double-bubble wrap offers better shock resistance, making it ideal for packaging larger and heavier items.

It's important to note that bubble wrap can be made from new materials or recycled materials.

The more new materials are used, the better the bubble wrap's brightness, transparency, and toughness.

Bubble wrap, as a versatile packaging material, has a wide range of applications and thus continues to hold significant development potential in the future.

Here are some factors for an in-depth analysis of the prospects for bubble wrap:

With the increasing focus on sustainability and environmental awareness, there is a growing demand for recyclable and renewable packaging materials. Bubble wrap can be a sustainable packaging choice, especially when made from recycled materials. Manufacturers may increasingly adopt sustainable production methods for bubble wrap to meet consumer demands for eco-friendliness.

As the e-commerce and online retail industries continue to grow, there is a need for secure and reliable packaging materials to protect products during transportation. Bubble wrap, with its excellent cushioning and protective properties, will continue to see widespread use in these sectors.

The expansion and complexity of global supply chains mean that more products require safe transportation over long distances. Bubble wrap's role in logistics and supply chain management will continue to strengthen.

Bubble wrap manufacturers can innovate by offering various types of bubble wrap to meet the diverse needs of different industries and applications.

For example:

(1) Bubble wrap with special features

(2) Anti-static bubble wrap

(3) Bubble wrap with thermal insulation properties

Bubble wrap has become a standard packaging material worldwide. With the growth of global trade and the rise of emerging markets, the demand for bubble wrap is likely to continue increasing.

Bubble wrap can not only protect products but also be integrated into creative packaging designs to enhance product appeal. Innovative packaging designs can drive the wider use of bubble wrap.

With increasing attention to waste management and recycling, the recycling and reuse of bubble wrap will become an important issue. Manufacturers and consumers may become more actively involved in recycling bubble wrap to promote sustainability.

Bubble wrap continues to have promising prospects for development in the future, particularly in areas related to sustainability, e-commerce, logistics, and innovation.

However, manufacturers need to adapt to changing market demands and focus on environmental and sustainability trends to ensure that bubble wrap continues to play a vital role in various applications.