- since 1985 -

- since 1985 -

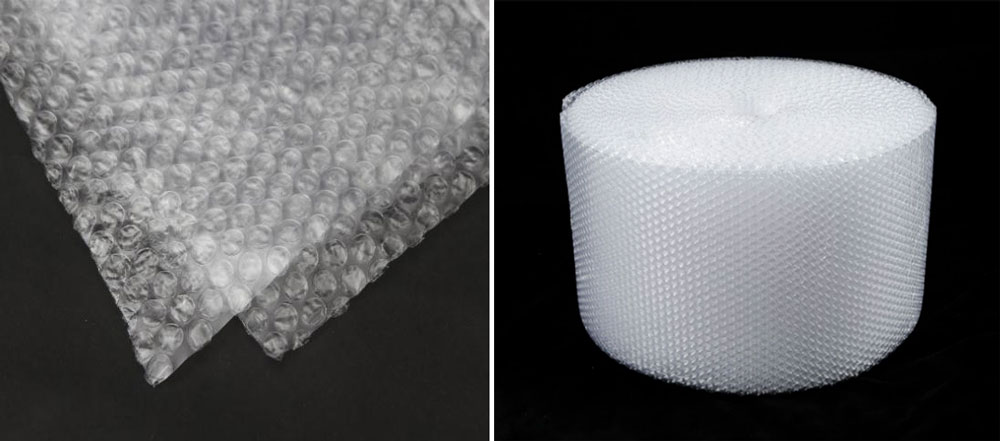

Air bubble film has become an indispensable part of the packaging industry. Its primary function is to provide exceptional protection to a wide variety of products. When it comes to shipping and storing items, the cushioning effect of air bubbles is crucial. They act as shock absorbers, effectively reducing the impact force that products may experience during transit. This makes air bubble film ideal for protecting delicate and fragile items such as electronics, where even a slight jolt can cause damage to sensitive components. Additionally, for glassware and ceramics, the air bubble film offers a buffer against vibrations and potential drops, minimizing the risk of breakage. It also provides protection against scratches and abrasions, ensuring that the product's surface remains intact. In essence, air bubble film is a reliable safeguard that gives businesses and consumers peace of mind when it comes to the integrity of packaged items.

* Consistent Thickness

The HLGP Bubble film machine is renowned for its ability to produce bubble films with remarkably consistent thickness. This consistency is vital as it ensures uniform protection across the entire surface of the packaged item. No matter where the product comes into contact with the bubble film, it receives the same level of cushioning, enhancing the overall reliability of the packaging. It also helps in maintaining a consistent appearance, which is not only aesthetically pleasing but can also contribute to brand image and professionalism in the eyes of customers.

* Excellent Transparency

The transparency of the bubble films produced by this machine is another outstanding feature. It allows for easy visual inspection of the packaged items without the need to open the packaging. This is especially beneficial for inventory management and quality control purposes. Retailers and distributors can quickly identify the products, check for any defects or damages, and ensure that the correct items are being shipped. Moreover, the transparency adds a modern and clean look to the packaging, making the products more appealing on the shelves.

* Superior Mechanical Properties

The bubble films have superior mechanical properties, enabling them to withstand greater stress and pressure. This means they can endure more rigorous handling and transportation conditions without compromising their protective capabilities. Whether it's being stacked in a warehouse or subjected to various forces during shipping, the films can effectively protect the products inside, reducing the likelihood of damage and ensuring that the products reach their destination in perfect condition.

* 100% Recycled Edge Materials

One of the most remarkable aspects of the HLGP Bubble film machine is its commitment to zero waste. The machine recycles 100% of the edge materials, which is a significant step towards a more sustainable packaging solution. By reusing these materials, it not only reduces waste but also conserves resources and reduces the environmental footprint associated with the production of bubble films. This aligns with the growing global demand for environmentally friendly packaging options and positions businesses that use the HLGP machine as leaders in sustainable practices.

* Use of Low-Density Polyethylene (LDPE)

The utilization of low-density polyethylene (LDPE) further enhances the machine's environmental credentials. LDPE is a widely used plastic material that is known for its relatively lower environmental impact compared to some other plastics. It is easier to recycle and has better compatibility with recycling processes. By using LDPE, the HLGP Bubble film machine helps to reduce plastic waste and minimize the negative impacts on the environment, contributing to a more sustainable future for the packaging industry.

* Automated Production and Labor Cost Reduction

The automated production process of the HLGP Bubble film machine is a game-changer in terms of cost-effectiveness. By reducing the need for extensive manual labor, businesses can significantly cut down on labor costs. With fewer workers required to operate the machine and oversee the production process, companies can allocate their resources more efficiently. This not only saves money in the short term but also improves the overall productivity and profitability of the packaging operation.

* Improved Cost-Effectiveness

The combination of high-quality production and efficient use of materials results in improved cost-effectiveness. The consistent thickness and quality of the bubble films produced by the HLGP machine mean that there is less waste and a higher yield of usable packaging material. This, in turn, reduces the cost per unit of packaging. Additionally, the durability and protection provided by the films can lead to fewer product returns and replacements due to damage during transportation, further saving businesses money in the long run.

* Enhanced Competitiveness in the Market

Businesses that invest in the HLGP Bubble film machine can gain a competitive edge in the market. The ability to produce high-quality, environmentally friendly, and cost-effective packaging solutions can attract more customers and win over clients who are increasingly conscious of sustainability and value for money. By offering better packaging options, companies can differentiate themselves from their competitors and build a stronger brand reputation, ultimately leading to increased market share and business growth.

* Reduced Damage during Transportation and Storage

The excellent mechanical properties and durability of the bubble films produced by the HLGP machine provide outstanding protection for products during transportation and storage. This reduction in damage has a direct impact on customer satisfaction. When customers receive their products in perfect condition, they are more likely to be satisfied with their purchase and have a positive perception of the brand. It also helps to reduce the number of complaints and returns, saving businesses time and money in dealing with post-purchase issues.

* Building Brand Reputation and Loyalty

By ensuring that products arrive intact, businesses can build a better brand reputation and foster customer loyalty. Customers are more likely to repeat purchases and recommend a brand to others when they have a positive experience with the packaging and the condition of the products received. The effective protection provided by the HLGP bubble films plays a crucial role in creating a seamless customer experience and strengthening the relationship between the business and its customers.

* Meeting Diverse Packaging Needs

The HLGP Bubble film machine understands that different products have unique packaging requirements. It offers personalized packaging solutions to accommodate a wide range of items and customer preferences. Whether it's a small, delicate item that requires a thinner and more flexible bubble film or a large, heavy object that needs a thicker and more robust packaging, the machine can be adjusted to meet these specific needs.

* Optimizing Packaging Effects and Economics

By providing customized options, the HLGP machine can achieve optimal packaging effects and economic benefits. It can help businesses reduce excess packaging material while still ensuring adequate protection, saving on costs and minimizing waste. At the same time, the personalized packaging can enhance the visual appeal and functionality of the packaging, making the products more attractive to consumers and improving the overall user experience. This balance between effectiveness and economy is a key advantage of the HLGP Bubble film machine's personalized packaging solutions.

The air bubble film machine plays a crucial role in the packaging industry, and the HLGP Bubble film machine from Hualiang Machinery Company stands out with its exceptional features and advantages. From producing high-quality bubble films with consistent thickness, excellent transparency, and superior mechanical properties to its commitment to environmental sustainability, cost-effectiveness, effective product protection, and personalized packaging solutions, it is a comprehensive and innovative solution that meets the diverse needs of businesses in today's competitive market. It truly represents a new standard in air bubble film production, providing a reliable and sustainable option for packaging professionals and contributing to the growth and success of businesses across various industries.