- Hydraulic changer:

- since 1985 -

- since 1985 -

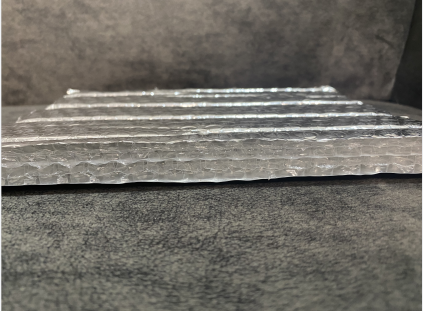

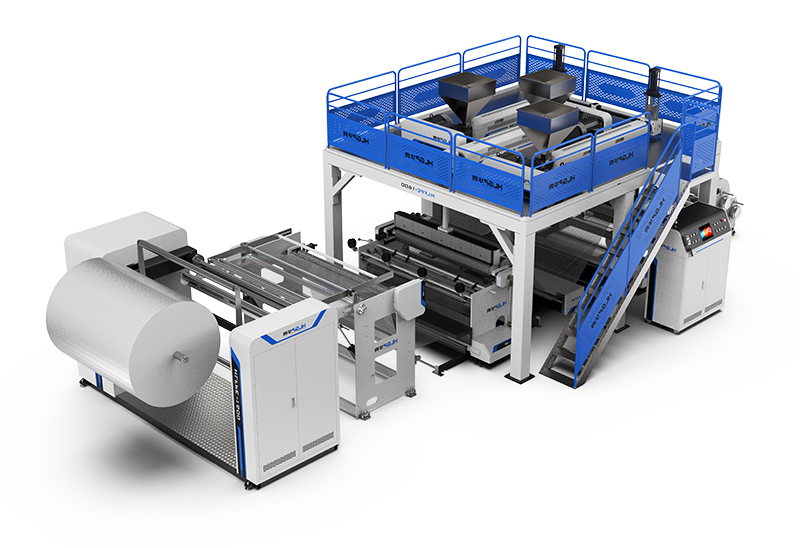

5-7 layers bubble film machine.The material is LDPE,LLDPE,HDPE.PP.etc

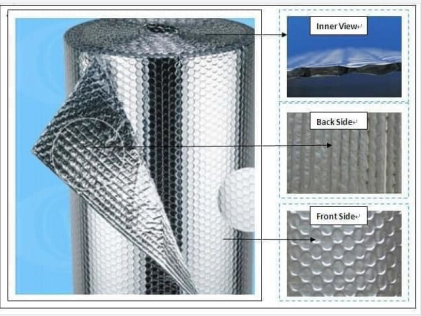

Unwinder can laminate materials like pearl wool, Kraft paper, and aluminum film to the outer layer of the bubble film.

The material of T-die is 45# steel and P20h or 2311#

Bubble are formed by bubble roller and water cooling for faster and higher-quality film production.

This model adopts a screw ratio of 34:1, which enables better utilization of plastic raw materials during the extrusion process. This allows for more efficient use of 100% recycled materials and reduces production costs.

One worker can operate 1-3 machines. Greatly improve production efficiency and utilization, and reduce labor costs.

Introducing 5-7 Layer Bubble Wrap: The Ultimate Protection!

Upgrade your packaging game with our cutting-edge 5-7 layer bubble wrap!

Improve production efficiency: 5-7 layer bubble film machines are usually equipped with automated control systems and high-speed production equipment, which can greatly improve production efficiency. The production speed of multi-layer bubble film is faster than that of single-layer bubble film, making it more suitable for large-scale production and commercial applications.

Wide application: 5-7 layers of bubble film are widely used in packaging, transportation, protection and other fields due to its better performance and adjustable performance. The design of the multi-layer structure can be adjusted and optimized according to the needs of different products, and is suitable for products of various shapes and sizes.

|

Model |

HLFPE-1600 |

HLFPE-2000 |

HLFPE-2500 |

HLFPE-3000 |

|

Product Width |

1600mm |

2000mm |

2500mm |

3000mm |

|

Screw dia |

70.60/60/70.60 |

80.70/70/80.70 |

80.70/70/80.70 |

90.80/80/90.80 |

|

L/D |

34:1 |

34:1 |

34:1 |

34:1 |

|

Output |

220Kg |

260Kg |

260Kg |

450Kg |

|

Motor |

22/15/15/22/15kw |

30/22/22/30/22kw |

30/22/22/30/22kw |

45/37/37/45/37kw |

|

Total power/Heating power |

205/105kw |

263/127kw |

271/135kw |

381/180kw |

|

L*W*H |

16000x4800x3200 |

16000x5100x3200 |

16000x5300x3200 |

16000x5500x3200 |

|

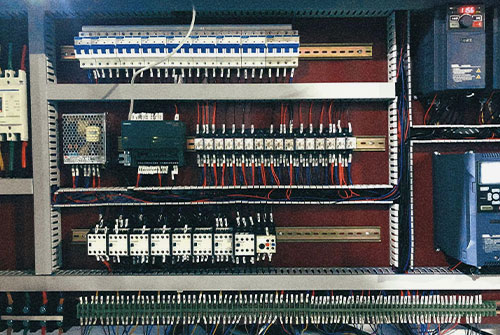

Volt/Ph/Line/Hz |

380/3/4/50 |

|||

|

Line speed |

35m/min |

|||

|

Material |

LDPE/LLDPE |

|||

|

Max Speed |

45M/min |

|||

|

Output |

Customized by configuration |

|||

Electricity Consumption (kWh) 24 hours

0.00 (degree)Finished Width (m)

0.00 (m)Finished thickness (thickness per square meter)

0.00Speed (per minute)

0.00Extrusion volume (24 hours)

0.00Raw material cost (per ton)

Labor origin (24 hours)

Labor origin (24 hours)

Total cost

0