- 10-inch Touchscreen

- since 1985 -

- since 1985 -

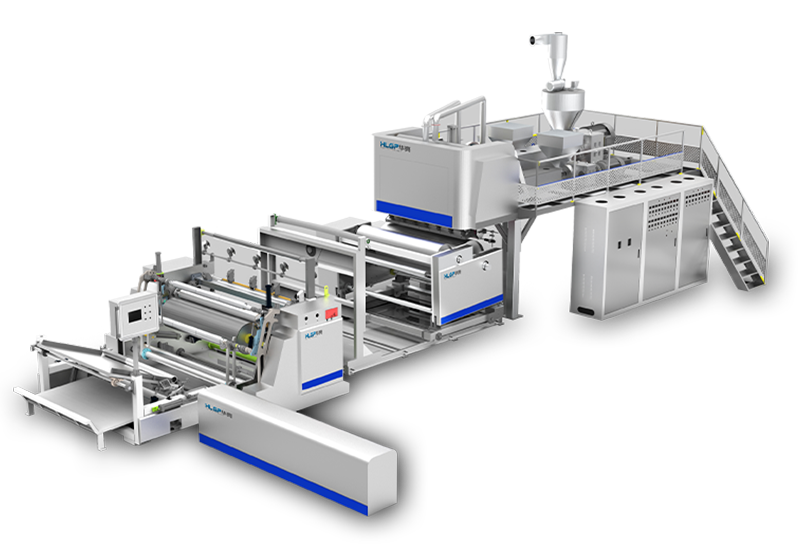

The machine's speed is designed to reach 200 meters per minute, and the working speed is stable between 150-200 meters per minute. Its production capacity is 320 kg/hour, but actual production capacity will vary based on film thickness and production line speed.

Impressively, the equipment only requires one operator to operate, increasing productivity and saving labor costs. Due to its high-speed operation, reliable production capacity and labor-saving design, this equipment will become a reliable and efficient solution for film production in various industrial situations.

Highlights on machine configuration:

1. The length-to-diameter ratio of the machine is 34:1, which effectively enhances the plasticizing process of plastic materials.

2. The screw is nitrided to significantly improve its stability and durability.

3. Equipped with fully automatic measurement, automatic winding, and automatic roll changing functions to simplify the production process and improve operating efficiency.

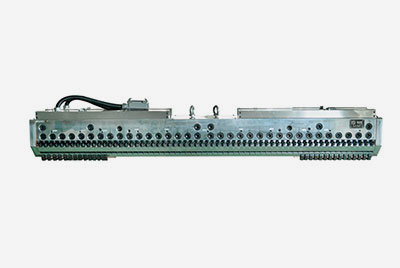

4. The T-shaped die head is made of 2311 die steel, which results in more uniform film output and longer service life.

5. By using metal hoses to connect water pipes, cooling efficiency is improved to ensure superior cooling effects.

6. The large diameter cooling roll was recently updated from the standard 720mm to 800mm, further improving the efficiency of the cooling process.

| No. | Item | Specs |

| 1. | Model | HLCPE-1500-90-65-65 |

| 2. | Industrial Power Supply | 3 phases industrial power supply |

| 3. | Total Power | 150 KW |

| 4. | Main Raw Material | LLDPE, & MLLDPE |

| 5. | Thickness of Film | 10~50 microns (minimum thickness can be 8 microns) |

| 6. | Width of the Useful Film | Maximum width: 1500 mm |

| 7. | Film Layer Structure | ABC Three layers or ACBCA Five layers |

| 8. | Designed Linear Speed | 200 M/Min |

| 9. | Extrusion Output | 320 kgs/h |

| 10. | Dimensions (L×W×H) | 12*6*3.8 M (for reference only) |

| 11. | Gross Weight | 16T (for reference only) |

Electricity Consumption (kWh) 24 hours

0.00 (degree)Finished Width (m)

0.00 (m)Finished thickness (thickness per square meter)

0.00Speed (per minute)

0.00Extrusion volume (24 hours)

0.00Raw material cost (per ton)

Labor origin (24 hours)

Labor origin (24 hours)

Total cost

0