- Hydraulic changer:

- since 1985 -

- since 1985 -

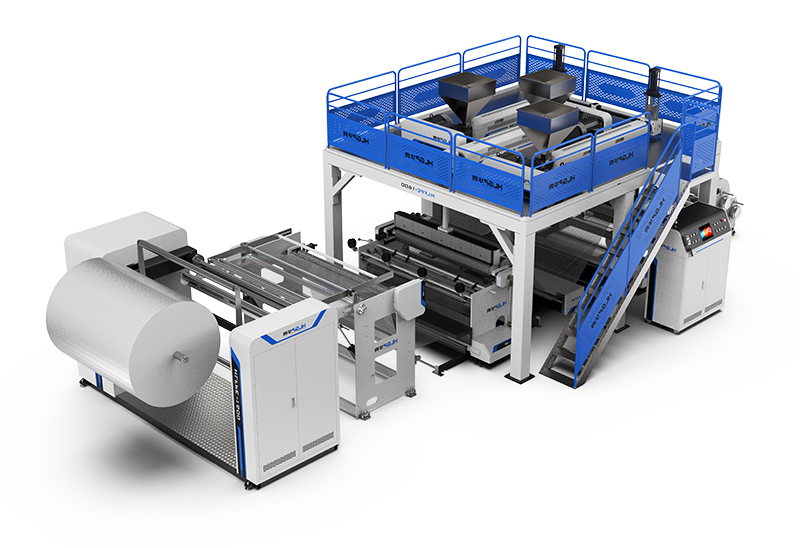

1. Speed design: Adopting a special design, the maximum speed can reach 37 meters/minute.

2. Working speed: The default working speed is 25 meters/minute, ensuring stable production efficiency and quality. Due to the machine's high-speed design, efficient production capabilities are maintained even at lower operating speeds.

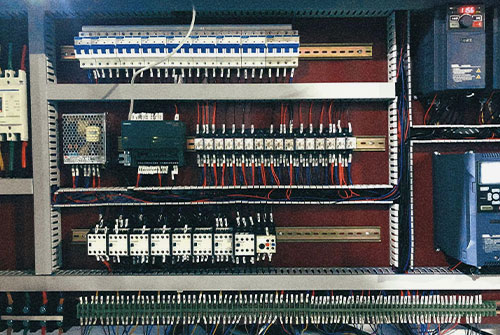

3. Supports optional British Bruker motors, Omron thermostats, Inovance or Yaskawa inverters and other internationally renowned electrical components. It has good performance and reliability, ensuring the stable operation and precise control of the machine.

1. Multi-layer structure: Compared with single-layer bubble film, 3-5 layers of bubble film have more layers. The multi-layer structure can increase the strength and durability of the bubble wrap, while also providing better protection. Different levels of structure can be designed according to different needs, allowing the preparation of more diversified bubble film products.

2. High-quality bubble film: The multi-layer structure makes the 3-5 layers of bubble film have better tear resistance, impact resistance and compressive strength. This high-quality bubble film can effectively protect packaged products, reduce damage to products, and provide better cushioning properties.

3. Save raw materials: Compared with single-layer bubble film, 3-5 layers of bubble film can utilize raw materials more effectively. Using a multi-layer structure, the thickness of the bubble film can be reduced while ensuring product performance, thereby saving the use of raw materials.

|

Model |

HLFPE-1600 |

HLFPE-2000 |

HLFPE-2500 |

HLFPE-3000 |

|

Product Width |

1600mm |

2000mm |

2500mm |

3000mm |

|

Screw dia |

70/60/60 |

80/70/70 |

80/70/70 |

90/80/80 |

|

L/D |

34:1 |

34:1 |

34:1 |

34:1 |

|

Output |

150Kg |

180Kg |

180Kg |

300Kg |

|

Motor |

22/15/15KW |

30/22/22KW |

30/22/22KW |

45/37/37KW |

|

Total power/Heating power |

155/95KW |

200/120KW |

200/120KW |

255/165KW |

|

L*W*H |

12000x4800x3200 |

12000x5100x3200 |

12000x5300x3200 |

12000x5500x3200 |

|

Line speed |

35m/min |

|||

|

Volt/Ph/Line/Hz |

380/3/4/50 |

|||

|

Material |

LDPE/LLDPE |

|||

|

Max Speed |

45M/min |

|||

|

Output |

Customized by configuration |

|||

Electricity Consumption (kWh) 24 hours

0.00 (degree)Finished Width (m)

0.00 (m)Finished thickness (thickness per square meter)

0.00Speed (per minute)

0.00Extrusion volume (24 hours)

0.00Raw material cost (per ton)

Labor origin (24 hours)

Labor origin (24 hours)

Total cost

0