- 10-inch touchscreen

- since 1985 -

- since 1985 -

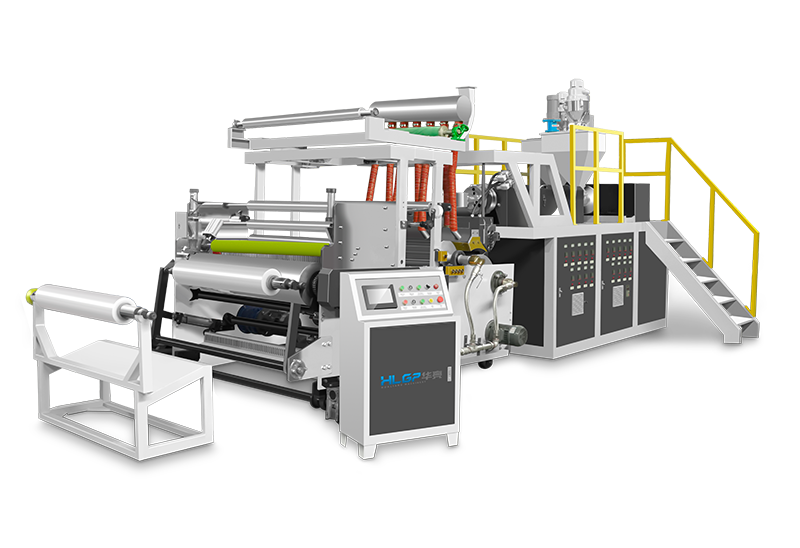

With a design speed of up to 150 meters/minute and a working speed of 80~120 meters/minute, it has excellent production capacity and power consumption ratio of approximately 0.38 kWh/kg.

The configuration of this machine has many highlights. First, the length-to-diameter ratio reaches 34:1, which further improves the plasticizing performance of plastic materials. Secondly, the screw has been nitrided to make it more stable and durable.

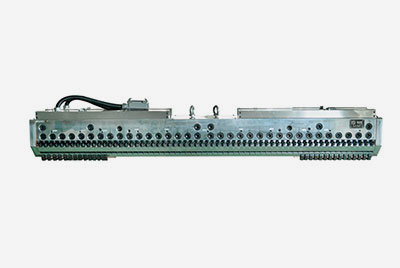

In addition, it is equipped with fully automatic metering, automatic winding and automatic roll changing functions, which greatly improves production efficiency. The T-shaped die head made of 2311 die steel not only makes the paint film more uniform, but also greatly extends the service life.

| No. | Item | Specs |

| 1. | Model: | HLCPE-1000-80/60 |

| 2. | Industrial Power Supply | 3 phases industrial power supply |

| 3. | Total Power | 100 KW |

| 4. | Main Raw Material | LLDPE, LDPE (few) & MLLDPE |

| 5. | Thickness of Film | 12~50 microns (minimum thickness can be 8 microns) |

| 6. | Width of the Useful Film | Maximum width: 1000 mm |

| 7. | Film Layer Structure | AB two layers or ABA three layers |

| 8. | Designed Linear Speed | 150 M/Min |

| 9. | Extrusion Output | 80~150 kgs/h |

| 10. | Dimensions (L×W×H) | 7*3*2 M (for reference only) |

| 11. | Gross Weight | 5500 (for reference only) |

Electricity Consumption (kWh) 24 hours

0.00 (degree)Finished Width (m)

0.00 (m)Finished thickness (thickness per square meter)

0.00Speed (per minute)

0.00Extrusion volume (24 hours)

0.00Raw material cost (per ton)

Labor origin (24 hours)

Labor origin (24 hours)

Total cost

0