- 10-inch touchscreen

- since 1985 -

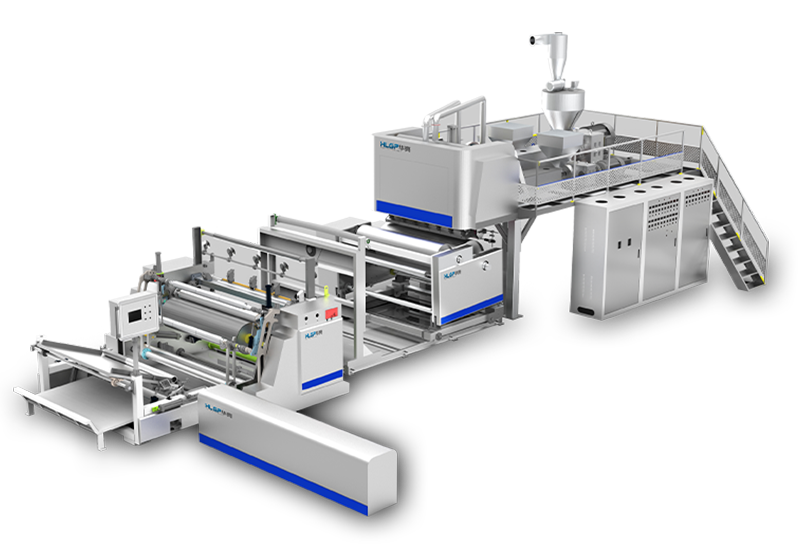

Professional Bubble Film Machine Manufacturer

- since 1985 -

Use a larger diameter cooling roller (upgraded from standard 800 mm to 1000 mm) to improve cooling efficiency, with a working speed of 150-200 m/min.

With its advanced features and configuration, this stretch film production machine can produce high-quality stretch film stably and efficiently. It has fully automatic metering, rewinding and roll changing functions. The production capacity can reach 400-600 kg/hour, only One operator is required to operate the machine.

| No. | Item | Specs |

| 1 | Model: | HLCPE-2000-120-80-80 |

| 2 | Industrial Power Supply: | 3 phases industrial power supply |

| 3 | Total Power: | 350 KW |

| 4 | Main Raw Material: | LLDPE, & MLLDPE |

| 5 | Thickness of Film: | 10~50 microns (minimum thickness can be 8 microns) |

| 6 | Width of the Useful Film: | Maximum width: 2000 mm |

| 7 | Film Layer Structure: | ABC Three layers or ACBCA Five layers |

| 8 | Designed Linear Speed: | 250 M/Min |

| 9 | Extrusion Output: | 400-600 kgs/h |

| 10 | Dimensions (L×W×H): | 14*6.5*5 M (for reference only) |

| 11 | Gross Weight: | 22T (for reference only) |

Electricity Consumption (kWh) 24 hours

0.00 (degree)Finished Width (m)

0.00 (m)Finished thickness (thickness per square meter)

0.00Speed (per minute)

0.00Extrusion volume (24 hours)

0.00Raw material cost (per ton)

Labor origin (24 hours)

Labor origin (24 hours)

Total cost

0