- 10-inch Touchscreen

- since 1985 -

- since 1985 -

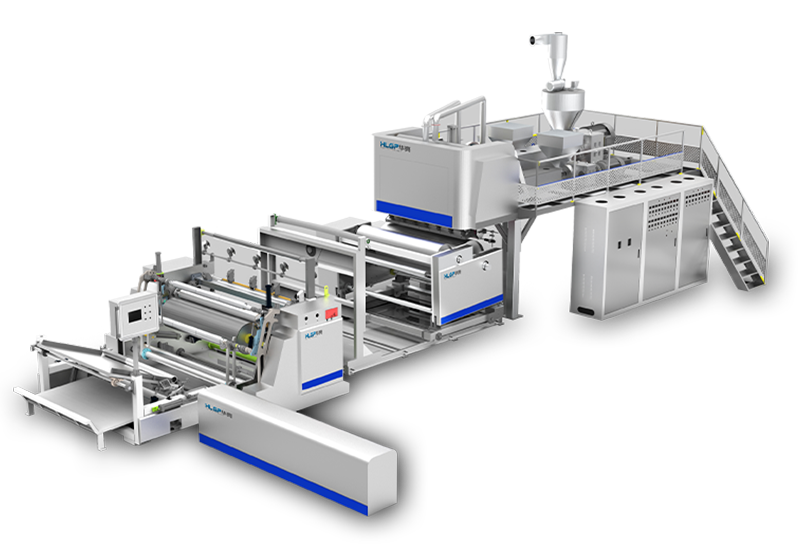

One of the advantages of the stretch film machine is that the speed is designed to be as high as 200 meters/minute. This fast working speed effectively increases production capacity up to 320 kg per hour (depending on film thickness and line speed). This means that the stretch film machine can complete a large number of packaging tasks quickly and efficiently.

In addition, due to the high degree of automation of the stretch film machine, only one worker can operate the machine. This simple operability makes the use of the machine more convenient and flexible, reducing labor costs and labor requirements.

To sum up, in addition to high-speed design and working speed, the stretch film machine also has high production capacity and ease of operation. It is a very superior machine and equipment for the logistics and packaging industry.

Highlights on machine configuration:

Stability: The stretch film machine can provide stable and uniform packaging effects, effectively protect items from damage and extrusion, and prevent items from loosening and shifting.

Versatility: The wrapping film machine has different packaging modes, which can be selected according to the characteristics and needs of the items, such as circumferential wrapping, line wrapping, etc.

Flexibility: The stretch film machine is suitable for packaging items of different types, shapes and sizes, and has greater adaptability and flexibility.

Energy saving and environmental protection: Compared with other packaging methods, the packaging materials used by the stretch film machine are more economical and can be recycled and reused, reducing resource waste and environmental pollution.

| No. | Item | Specs |

| 1. | Model | HLCPE-1500-90-65-65 |

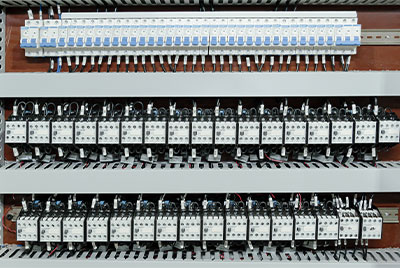

| 2. | Industrial Power Supply | 3 phases industrial power supply |

| 3. | Total Power | 150 KW |

| 4. | Main Raw Material | LLDPE, & MLLDPE |

| 5. | Thickness of Film | 10~50 microns (minimum thickness can be 8 microns) |

| 6. | Width of the Useful Film | Maximum width: 1500 mm |

| 7. | Film Layer Structure | ABC Three layers or ACBCA Five layers |

| 8. | Designed Linear Speed | 200 M/Min |

| 9. | Extrusion Output | 320 kgs/h |

| 10. | Dimensions (L×W×H) | 12*6*3.8 M (for reference only) |

| 11. | Gross Weight | 16T (for reference only) |

Electricity Consumption (kWh) 24 hours

0.00 (degree)Finished Width (m)

0.00 (m)Finished thickness (thickness per square meter)

0.00Speed (per minute)

0.00Extrusion volume (24 hours)

0.00Raw material cost (per ton)

Labor origin (24 hours)

Labor origin (24 hours)

Total cost

0