- Hydraulic changer:

- since 1985 -

- since 1985 -

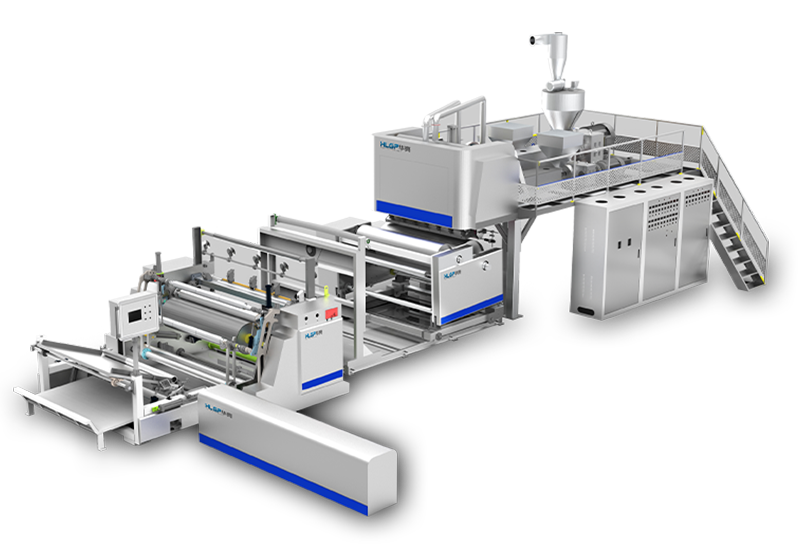

Working speed:150-200m/min

Production capacity:200-400kgs/h

Thickness of Film: 8~50 microns

Screw L/D ratio is 34:1

1.Multilayer Structure: The machine is designed with a Five-layer structure, enhancing the overall performance and functionality of the casting film.

2. Efficient Packaging: Engineered for machine-packing applications, the casting film machine ensures efficient and reliable packaging processes, contributing to increased productivity and cost-effectiveness.

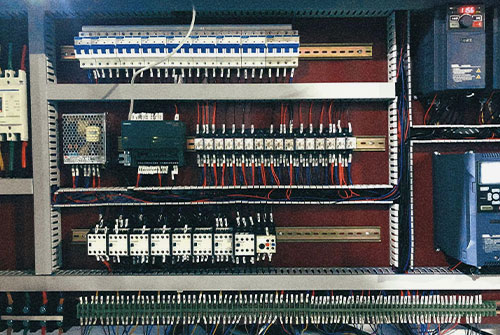

3. Automation and Energy Efficiency:

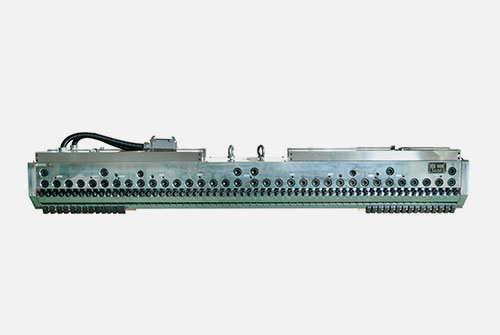

Imported automatic dies and energy-efficient motors ensure low energy consumption and high automation.

Offers cost-effective formulas to meet diverse customer needs.

4. Formula Precision and Labor Cost Reduction:

Auto dosing and mixing system enhances formula precision.

Reduces labor costs and ensures consistent product quality.

5. Film Cutting and Roll Changes:

Latest winding system allows instant film cutting and quick roll changes.

Reduces waste and overall costs.

Weightless automatic dosing system ensures formula accuracy, contributing to labor cost savings.

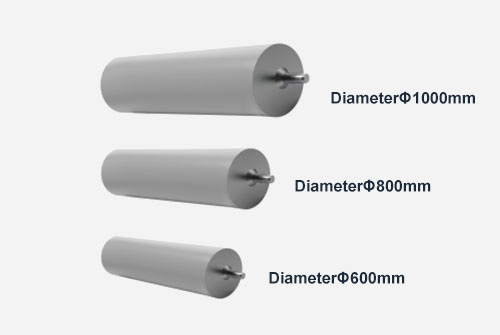

6. Cooling System:

Cooling roller with a major diameter and special flow for efficient cooling under high-speed production.

7. Stable Extrusion:

Professional screw design, gem treatment device, and air-cooling heating contribute to stable extrusion.

| No. | Item | Specs |

| 1 | Model: | HLCPE-2000-120-80-80 |

| 2 | Industrial Power Supply: | 380V |

| 3 | Total Power: | 360 KW |

| 4 | Main Raw Material: | LLDPE, & MLLDPE |

| 5 | Thickness of Film: | 10~50 microns (minimum thickness can be 8 microns) |

| 6 | Width of the Useful Film: | Maximum width: 2000 mm |

| 7 | Film Layer Structure: |

BADAC Five layers |

| 8 | Designed Linear Speed: | 200M/Min |

| 9 | Extrusion Output: | 200-400 kgs/h |

| 10 | Dimensions (L×W×H): | 14*6.5*5 M (for reference only) |

| 11 | Gross Weight: | 22T (for reference only) |

Electricity Consumption (kWh) 24 hours

0.00 (degree)Finished Width (m)

0.00 (m)Finished thickness (thickness per square meter)

0.00Speed (per minute)

0.00Extrusion volume (24 hours)

0.00Raw material cost (per ton)

Labor origin (24 hours)

Labor origin (24 hours)

Total cost

0