- since 1985 -

- since 1985 -

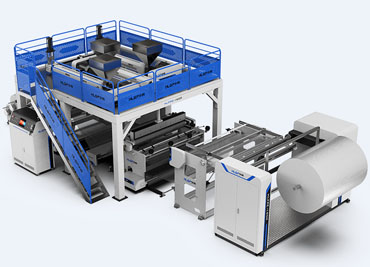

Bubble film machine, also known as bubble packaging machine or air cushion machine, is a machine specially used to produce bubble wrap. Bubble wrap is a packaging material composed of evenly spaced, raised, air-filled bubbles. Due to the cushioning properties of bubble film, it is widely used to protect fragile items during transportation and handling.Here's the breakdown of features and functions of a bubble wrap machine:

-Production of Bubble Wrap

The primary function of a bubble film machine is to create bubble wrap by forming plastic film into sheets with air-filled bubbles. These bubbles provide cushioning that helps protect items from damage during transit.

-Material Feeding

The machine typically uses rolls of plastic film (usually polyethylene) as the raw material. The film is fed into the machine where it is processed to form bubbles.

-Bubble Formation

The machine uses a series of rollers and molds to shape the plastic film into bubbles. Air is injected between layers of film to create the bubbles, which are then sealed to maintain their shape.

-Heating and Sealing

The machine often incorporates heating elements to seal the bubbles and ensure they hold their air. This involves thermal bonding processes that fuse the layers of plastic together around the air pockets.

-Cutting and Winding

After the bubble wrap is formed, the machine will cut the material into desired lengths and wind it onto rolls for easy handling and storage.

-Customization Options

Modern bubble film machines can be adjusted to produce different sizes and patterns of bubbles depending on the specific needs of the user.

-High Degree of Automation

Modern bubble film machines are equipped with highly automated control systems, including PLC (Programmable Logic Controller) programming and automatic material feeding systems, which greatly improve production efficiency and product consistency.

-Diverse Production Capabilities

The machine can produce bubble film in various specifications and sizes, including different bubble sizes and film thicknesses, to meet different packaging needs.

-Ease of Operation

The machine is designed with user-friendly interfaces, making it easy to learn and operate, thus reducing the training time and difficulty for operators.

-High-Quality Output

Through precise molds and roller designs, bubble film machines can produce high-quality bubble film with uniform bubbles and good sealing properties, ensuring reliable packaging.

-Easy Maintenance

Modern machines often have self-diagnostic systems that can monitor operational status in real-time and prompt maintenance needs, extending the machine's lifespan.

in short

Bubble film machine feature high production efficiency, capable of flexibly manufacturing various specifications of bubble film. Their highly automated design enhances production efficiency and product consistency. They use eco-friendly materials, minimizing environmental impact, and are user-friendly with easy maintenance, making them crucial equipment in the modern packaging industry.