- since 1985 -

- since 1985 -

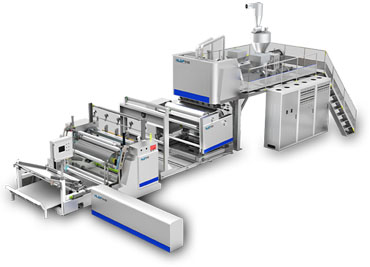

Stretch Film Making Machine is a specialized industrial equipment used to produce stretch film, which is a highly stretchable plastic film commonly used for wrapping and securing palletized goods during transportation and storage. Here's a detailed overview of its features, functions, and operational processes:

-Extrusion Process:

Stretch film making machines primarily operate through the extrusion process. This involves melting plastic resin pellets (such as LLDPE - Linear Low-Density Polyethylene) and extruding them through a flat die to form a continuous thin film.

-Layering Technology:

Advanced machines may incorporate multi-layer extrusion technology. This allows for the creation of stretch films with specific properties, such as improved puncture resistance, clarity, or UV protection.

-Automatic Controls:

These machines are highly automated, with precise control systems for managing parameters like film thickness, width, stretchability, and winding tension.

-Winding Mechanism:

They include mechanisms for winding the extruded film into large rolls suitable for industrial use. Automatic roll changers and tension controls ensure consistent winding quality.

-Customization Options:

Some machines can be equipped with features for adding additives or colors to the film during production, as per customer requirements.

-Material Feeding and Melting:

Plastic resin pellets are fed into an extruder where they are melted and mixed before being forced through a die.

-Extrusion and Cooling:

The molten plastic is extruded through a flat die to form a continuous sheet of stretch film. Cooling mechanisms solidify the film as it exits the die.

-Stretching and Orientation:

The film passes through stretching rollers, where it is elongated to impart stretchability and mechanical strength. This process aligns polymer molecules to enhance the film's properties.

-Winding and Cutting:

The stretched film is wound into large rolls using automated winding systems. Automatic cutters may trim the film to desired widths and lengths before winding onto the core.

-Quality Control:

Integrated sensors and monitoring systems continuously check parameters such as film thickness, stretch ratio, and roll tension to ensure consistent product quality.

3.Conclusion:

In summary, a Stretch Film Making Machine is a sophisticated piece of equipment designed for the efficient production of stretch films used in industrial packaging applications. Through extrusion, stretching, and winding processes, these machines create high-quality films that ensure secure and stable packaging of goods during transit and storage. Their role in modern logistics and supply chain management underscores their importance in ensuring product integrity and cost-effective packaging solutions.

HLGP is a professional manufacturer of stretch film making machines. For more information about us, please visit https://www.hlgpmachine.com/